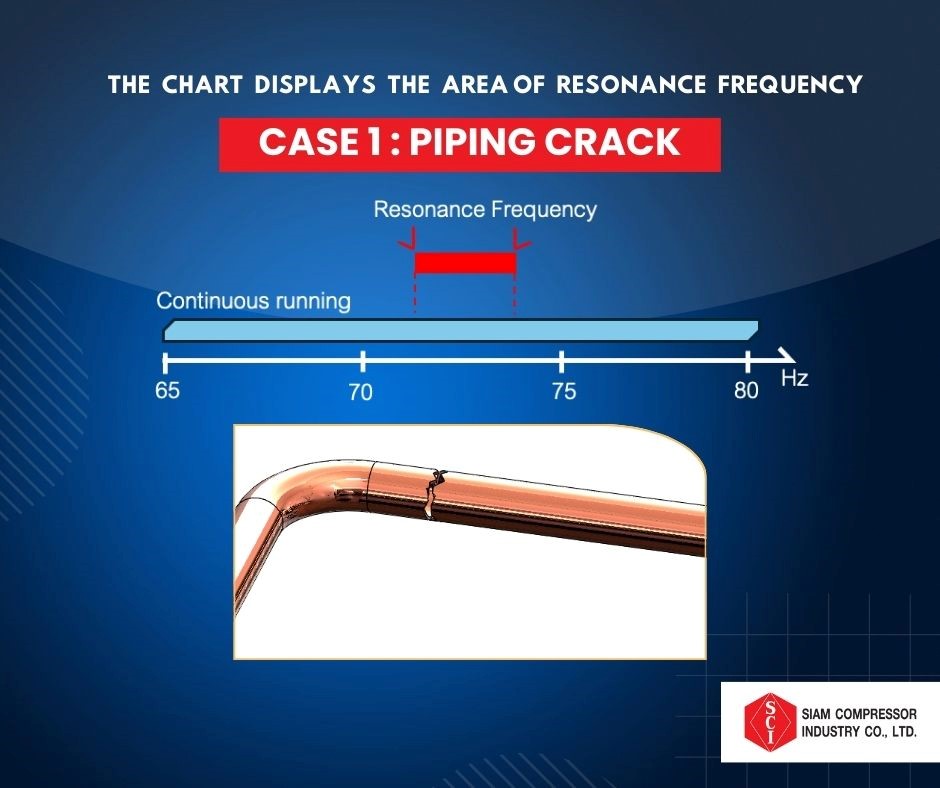

The design of refrigerant piping systems or other equipment is crucial to the efficiency of a cooling system and also impacts its operational safety. Generally, the design of these systems must consider several factors, such as length and pipe size. Another important aspect is designing the pipes to avoid natural frequencies. This is because if the operating frequency of the compressor falls within the natural frequency range, resonance frequency phenomena will occur, resulting in severe vibrations that may damage the piping system. Especially for the operation of inverter compressors, which have a wide range of frequency or motor speed adjustments, making the pipe design more complicated and intricate.

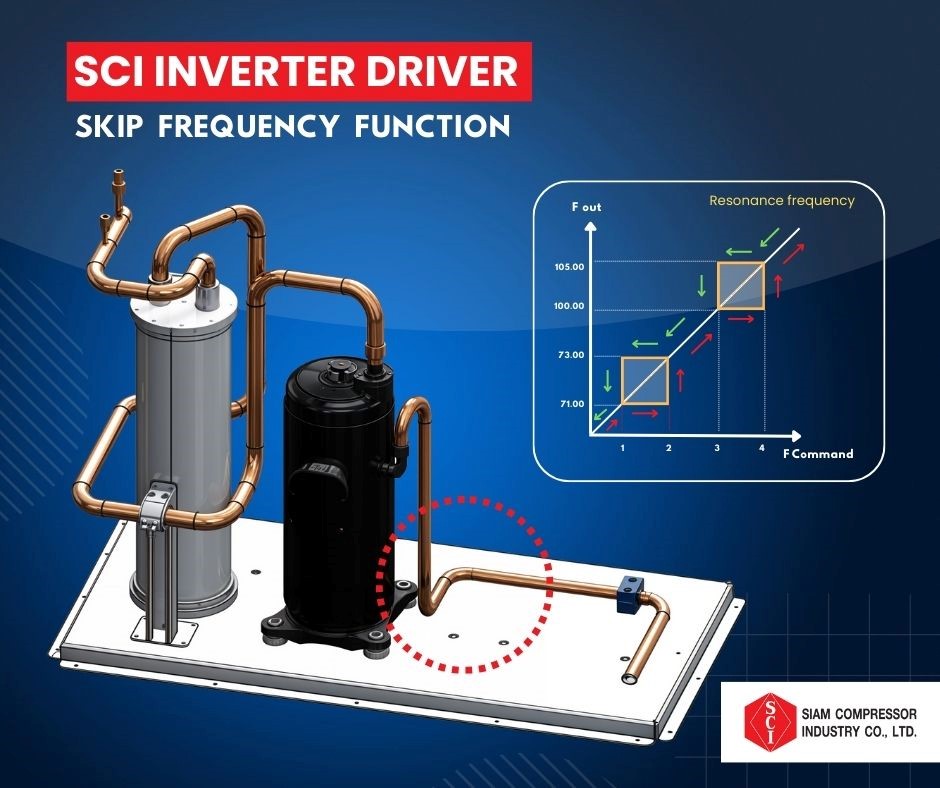

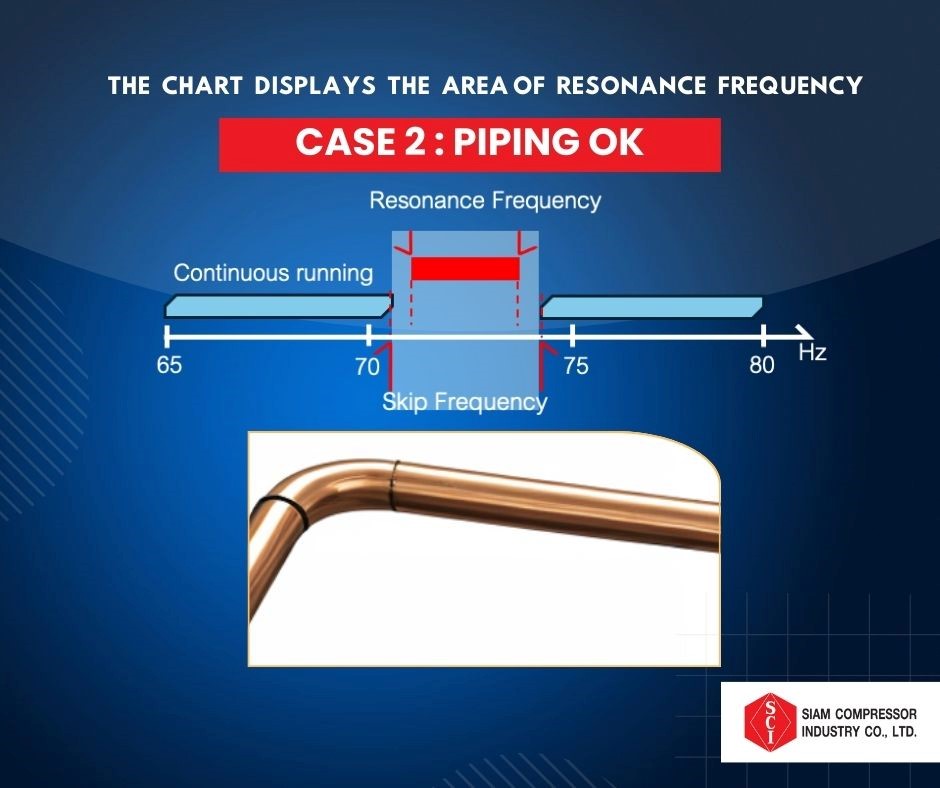

To address this issue, SCI developed the Skip Frequency function in the SCI Inverter Driver, allowing system designers to set frequencies that may cause natural frequency resonance. The SCI Inverter Driver will then monitor the operational frequency commands and avoid changing the frequency to any value within the set range to prevent resonance frequencies.

The system will only resume normal frequency operations once the command is outside the specified Skip Frequency range.

The SCI Inverter Driver function has two main features:

1. Users can set up to 5 skip frequency ranges.

2. The adjustable frequency values can be fine-tuned to an accuracy of 0.01 Hz.

In summary, the Skip Frequency function of the SCI Inverter Driver is designed to prevent potential issues with the piping system and enhance the efficiency and safety of inverter compressor operations. This is part of SCI's integrated solution, which aims to innovate and develop to truly meet customer needs and improve the quality of use.